Storm Water Technology Fact Sheet: Baffle Boxes

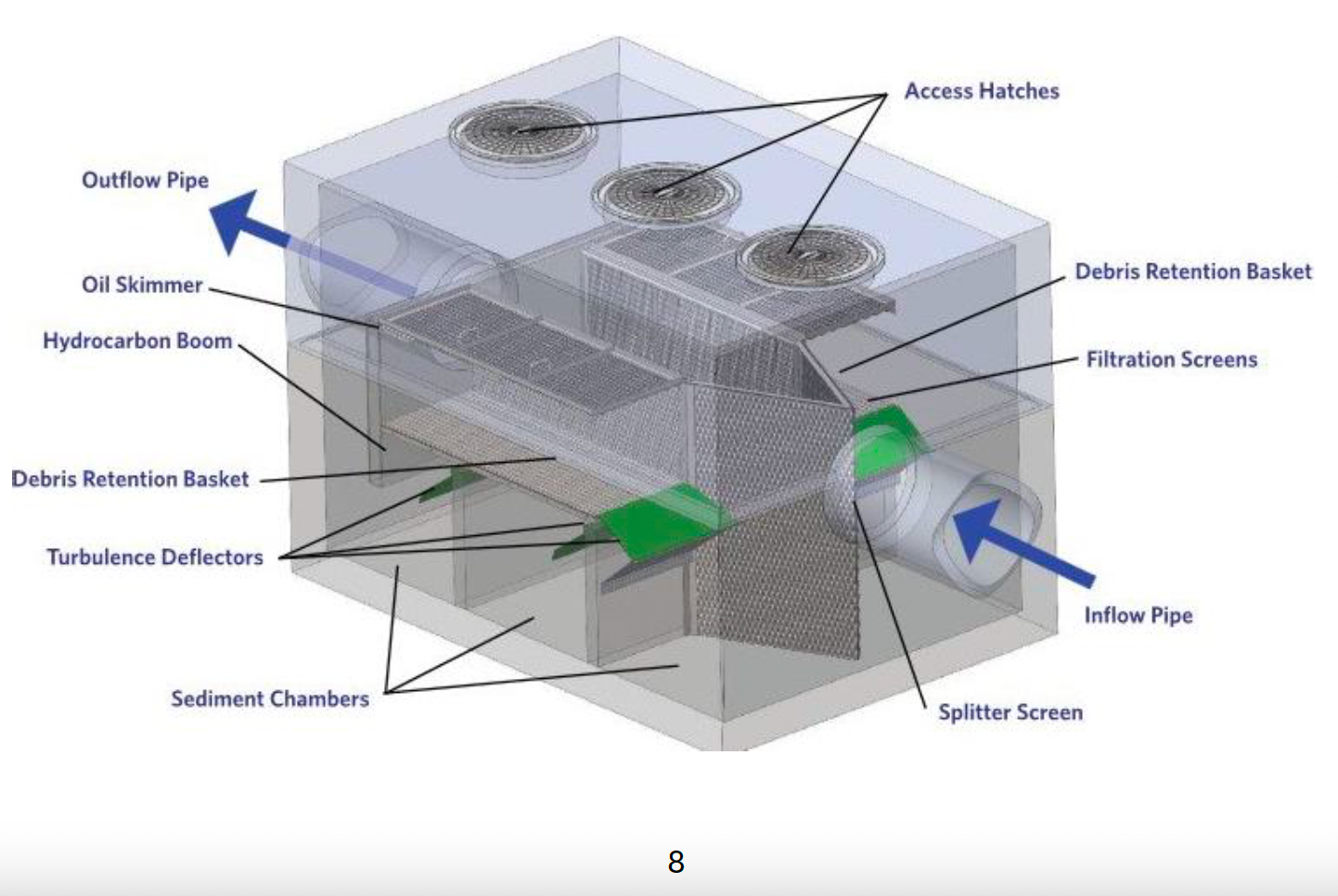

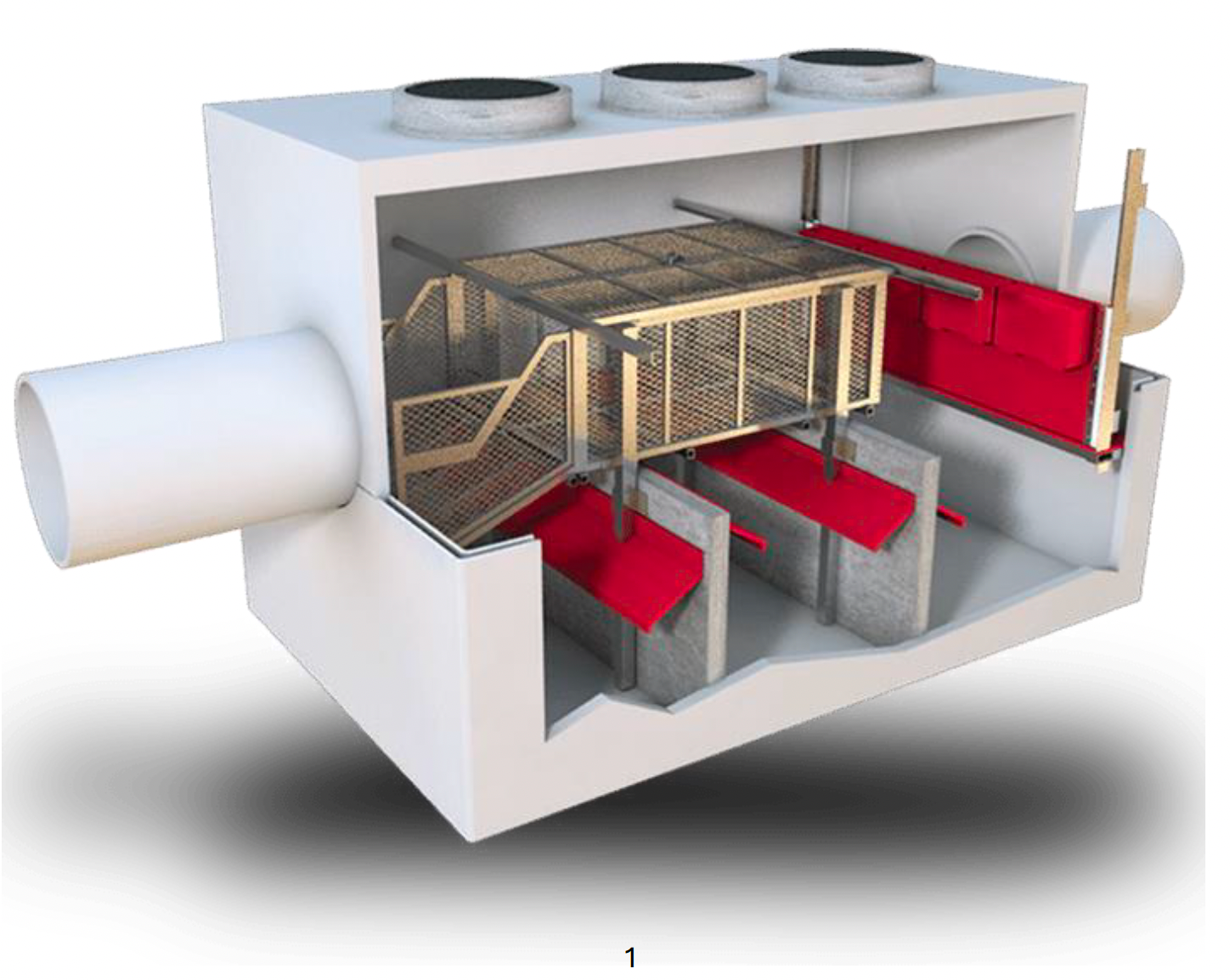

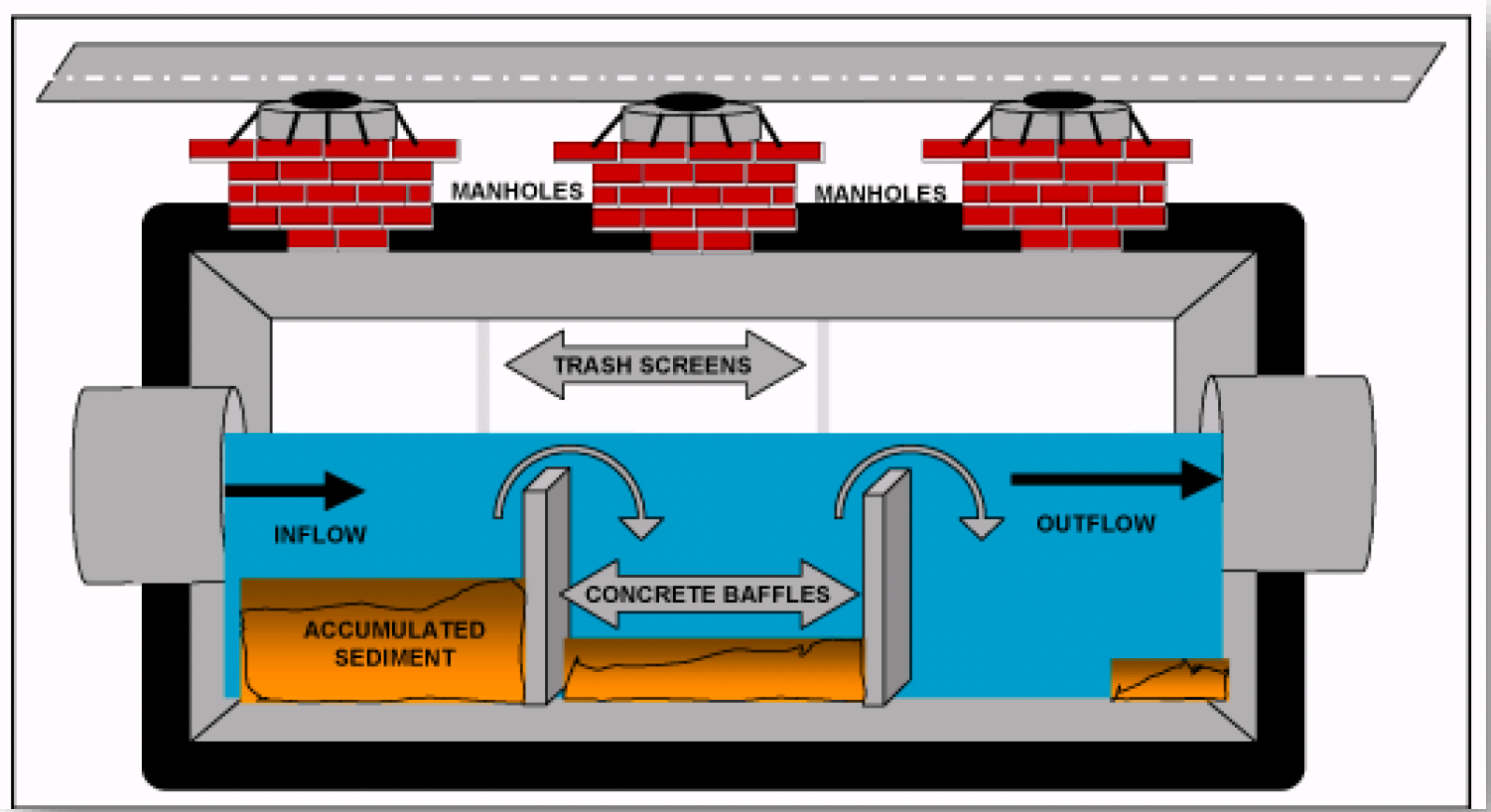

Baffle boxes are concrete or fiberglass structures containing a series of sediment settling chambers separated by baffles. The primary function of baffle boxes is to remove sediment, suspended particles, and associated pollutants from storm water. Baffle boxes may also contain trash screens or skimmers to capture larger materials, trash, and floatables. Baffle boxes are located either in-line or at the end of storm pipes. Figure 1 shows a typical baffle box design. The use of baffle boxes for pollutant removal is based on the concept of slowing the flow velocity through the box, thereby allowing solids and associated pollutants to settle to the bottom of the box. Storm water enters the box and begins to fill the first chamber. As water encounters the baffles, flow velocity decreases, allowing particles with a settling velocity greater than the horizontal flow velocity to settle to the bottom of the box. In addition to decreasing flow velocities, the baffles impede particle movement. As suspended solids strike the baffles they begin to settle. Larger particles usually settle out first and accumulate in the first chambers while smaller particles usually settle out in subsequent chambers.

APPLICABILITY

Baffle boxes have proven effective in removing sediment from storm water runoff. They are mainly utilized in areas where sediment control is a primary concern, while other storm water Best Management Practices (BMPs) may be more effective in areas where additional storm water pollutants, such as dissolved nutrients, oil and grease, or metals, are prevalent. Florida has used baffle boxes for several years. By 1998, Brevard County, Florida, had 42 baffle boxes serving residential areas, collecting runoff from lawns, driveways, and streets. Sediment accumulation in the baffle boxes varies greatly and depends on site characteristics such as drainage area, land use, soil type, and slope. In addition, non-wet weather flows, such as runoff from domestic activities like washing cars or watering lawns, can increase sediment contributions to storm sewers. Baffle boxes are ideally suited for retrofitting into existing storm pipes. Baffle boxes for pipes up to 48 inches in diameter can be precast, making installation quick and cost-efficient. Baffle boxes can be used for pipes up to 60 inches in diameter, but these boxes must be cast in place, making them more expensive and time-consuming to install. Baffle boxes are principally designed for sediment removal, but trash racks, screens, or skimmers can be installed to trap floatables and oil and grease as well.

ADVANTAGES AND DISADVANTAGES

Baffle boxes are simple, inexpensive storm water BMPs that effectively remove sediment and suspended solids from storm water. A primary advantage of baffle boxes is that they can be retrofitted into existing storm lines, allowing installation within existing rights-of-way. This is especially important in areas where land is unavailable or too expensive for other storm water BMPs. A major disadvantage of baffle boxes is that they require significant maintenance to remove accumulated sediment. If the boxes are not cleaned regularly, subsequent storms may resuspend the accumulated sediment and carry it out of the box, reducing the overall pollutant removal efficiency. Also, because many trash racks installed in baffle boxes are hinged at the top to prevent damage from high hydraulic pressure, they may release accumulated trash during high flows. Based on their experience with baffle boxes, officials in Brevard County recommend checking and cleaning them every two to three months during the dry season, and every month during the wet season (Bateman, et. al., 1998, and National Resources Defense Council, 1999). Another disadvantage is that baffle boxes are not designed for nutrient removal and may not be an appropriate storm water BMP if nutrients are a problem at a particular site. However, because baffle boxes effectively remove suspended materials, nutrients attached to sediments may settle out in the box. In general, modeling results show that baffle boxes are more effective at removing larger particles and less effective at removing smaller particles.

Schematic Drawing-Baffle Box

DESIGN CRITERIA

The design concept of a sediment [baffle] box is similar to the design of a three-chamber water quality inlet (also known as an oil/grit separator). Many of the earliest baffle boxes were, in effect, modified septic tanks. Typical baffle boxes are 3 to 5 meters (10 to 15 feet) long, 0.6 meters (2 feet) wider than the pipe, and 2 to 2.7 meters (6 to 8 feet) high. Weir height is usually 1 meter (3 feet). Weirs are usually set at the same level as the pipe invert to minimize hydraulic losses.

Manholes are set over each chamber to allow easy access for cleaning and maintenance. Manholes should be located within 15 feet of a paved surface to allow access by vacuum trucks for box maintenance. The design of the baffle box can be modified to promote easy cleaning and to prevent nutrient leaching from accumulated biota. Some fiberglass baffle boxes have been designed to include sliding grates on both ends. These gates are closed during cleaning to block flow, allowing removal of accumulated sediments and trash without vacuuming up incoming or residual flows. These baffle boxes also have rounded bottoms that cause accumulated sediment to collect in the middle of the box, making it easier to vacuum it out.

Baffle boxes can also be designed with aluminum screens installed below the inflow pipe but above the baffles. In this design, incoming flow drops through the screen, trapping trash, yard waste, and other debris away from the accumulating water below. Leaching is reduced because this debris is kept out of standing water. 4

Therefore, there is less chance of introducing nutrients into the outflow. Trash deflectors are set at the outflow end of the box, reducing the chance of carrying garbage out with excess flow. Preliminary modeling by the Florida Institute of Technology indicates that these screens do not become clogged even under heavy loads of debris. As flow accumulates in the first chamber, it is forced over a baffle into the next chamber. Flow deflectors at the top of the baffle reduce the possibility of sediment being carried from one chamber to the next. Flow exits through the outlet pipe.

Possible modifications to a standard baffle box design to accommodate site-specific conditions include:

• a two-chamber box for small pipes and small drainage areas;

• a three-chamber box for larger pipes; and

• two multi-chambered boxes in a series. These design modifications have not been fully studied. However, the Florida Institute of Technology used hydraulic scale-modeling to evaluate box size and shape, along with baffle size and placement, on pollutant removal efficiency. Using three, four, and five-chambered baffle boxes, this study evaluated the sediment removal efficiencies of fine and coarse-grained sediments under several typical flow rates and sediment concentrations. The researchers also evaluated the effect of changing the depth of the box and raising the height of the baffles. The results showed that, in general, adding more chambers to the box did not increase sediment removal because each chamber became shorter, and thus sediment did not settle out as efficiently. Resuspension of sediments in the box was a consistent problem because incoming flow disturbed sediments that had already settled, causing them to be resuspended and carried out of the settlement chamber.

The study suggested that reducing resuspension in the box would increase its overall efficiency, but this has not been investigated. A project to evaluate two baffle boxes in a series is underway at Sunset Park in Indiatlantic, Brevard County, Florida. This site consists of 23.8 acres of medium-density residential properties and 0.3 acres of highway. One baffle box was installed on a 24-inch pipe in 1992. Flow entered the box at a 90-degree angle relative to the length of the box and the weirs, forcing the flow to turn before entering the second chamber. This box removed approximately 8,490 pounds of sediment per year during the study period. A second baffle box was installed upstream of the original box in February 1998, with the goal of removing more sediment from the system. However, preliminary results indicate that overall sediment removal efficiencies have not increased (see Performance section below). 5

While 5,639 pounds of sediment per year are currently being removed by the upstream box, the downstream box only removes an additional 715 pounds per year. This slight increase in overall removal efficiencies indicates that the addition of a second box in a series is not a major design improvement for this system.

PERFORMANCE

Baffle boxes are an effective BMP to remove sediments from storm water. Baffle boxes have been shown to remove from 225 to 22,500 kilograms (500 to 50,000 pounds) of sediment per month, depending on the sediment load feeding into the baffle box. However, pollutant removal efficiencies (e.g., the percentage of pollutants removed by the BMP) depend on factors such as land use, drainage basin area, soil types, storm water velocities through the box, and the frequency and thoroughness of box cleaning. Limited data exists on the pollutant removal efficiencies of baffle boxes. Only one laboratory and one field evaluation are complete, while several more field tests are scheduled for the future. Results to date are discussed below. Sediment accumulation in baffle boxes varies greatly depending on the season and the amount and intensity of rainfall events. For example, Brevard County, Florida, monitored baffle boxes in the communities of Indiatlantic and Micco between 1992 and 1994. In a one-month period between August 21 and September 22, 1992, the Indiatlantic baffle box removed 2,040 kilograms (4,500 pounds) of sediment. This time of year (the summer season) is characterized by high intensity, short duration storms. However, in contrast, over a four-month period from September 1992 through January 1993 (during the winter season of lower intensity, longer duration storms), the box removed only 1,815 kilograms (4,000 pounds) of sediment. Monitoring of the baffle boxes included both water column and sediment samples. Measuring the concentration of contaminants in samples at both the inlet and outlet of the baffle box showed that the concentration of contaminants was reduced from the inflow to the outflow of the Indiatlantic box (see Table 1). Analysis of this site indicated removal rates of 71 percent Total Suspended Solids (TSS) and 38 percent phosphorous.

Analysis of BOD removal on three dates showed an average of 39 percent removals for two dates, but a 25 percent increase in BOD from inlet to outlet on a third date. Results from the Micco site baffle box were even more inconsistent, showing an increase in concentrations of some contaminants through the box. The researchers suggest that these increases may be due to inadequate cleaning and the resuspension of accumulated contaminants. Analysis of the sediments from the boxes, found that larger particles (primarily coarse, large-grained sand) were trapped in the first chamber of the baffle box, while finer particles (primarily fine organic and metals-rich sediments) settled out in subsequent chambers. In assessing these data along with removal efficiencies, the researchers concluded that 6

resuspension of sediments from the second and/or third chambers of the box could increase organic materials and metals in the outflow from the box, especially if the box had not been cleaned recently. A scale model test at the Florida Institute of Technology indicated that baffle boxes can remove up to 90 percent of coarse sediments at pipe velocities of 183 centimeters per second (6 feet per second). Removal of smaller fly ash particles is roughly 28 percent at the same velocities. The removal rate for coarse sediments remained constant even as sediment concentrations increased from 50 mg/L to 1000 mg/L. In contrast, removal efficiencies increased for finer sediments as sediment concentrations increased. This study also showed that an increase in the inflow rate decreased removal efficiencies. For coarser sediments, removal efficiencies declined slightly as the inflow rate increased, while removal rates for finer sediments decreased significantly as inflow rates increased. Thus, the pollutant removal efficiency of a baffle box may depend on both site-specific conditions and the characteristics of individual runoff events. More studies are either planned or underway to assess baffle box performance. Officials in Jacksonville, Florida, plan to monitor the performance of a baffle box installed on a 48-inch pipe as part of the city’s Storm Water Master Plan (City of Jacksonville Department of Public Works, 2000). This baffle box should be installed by early 2001, with performance monitoring beginning soon thereafter. The City of Gainesville, Florida, will also begin performance monitoring of a baffle box to gather information as part of their Storm Water Phase II program. Brevard County plans to continue monitoring the Sunset Park site, where two baffle boxes were installed in a series (

OPERATION AND MAINTENANCE

The key to the successful performance of a baffle box is regular maintenance, including routine inspection and cleaning. As sediment accumulates in the box, the chance for resuspension of accumulated material increases, and pollutant removal efficiencies can decline. Standing water that accumulates in the baffle box may become stagnant, leading to odor problems (England, 1996) and problems with mosquito breeding. It is important to establish a routine schedule to check the boxes and clean out accumulated sediment.

Boxes may accumulate anywhere from 225 to 22,500 kilograms (500 to 50,000 pounds) of material per month. The baffle boxes installed in Florida require monthly cleaning during the wet season and cleaning every two to three months during the dry season. However, maintenance schedules depend on individual site characteristics, including typical sediment loads, the size of the sewershed, flow rates, land use in the area, and the size of the box. For example, a baffle box in a small sewershed that does not receive much runoff will probably not need to be inspected as frequently as a baffle box serving a larger area. The size of the box may also impact the maintenance schedule. In general, the deeper the box, the longer it can function before needing maintenance. 7

Baffle boxes in Brevard County are cleaned by vacuum trucks on a regular schedule of two to six times per year. Originally, a private contractor performed the cleaning, but as the number of baffle boxes increased, the County determined that it was more cost effective and efficient to purchase a truck and perform the maintenance itself. Brevard County currently divides the use of one its vacuum trucks between pipe cleaning and baffle box clean out. During the wet season, the truck is scheduled primarily for baffle box maintenance; during the dry season, baffle boxes do not accumulate as much sediment and the truck is used primarily for pipe maintenance.

During a baffle box clean out, vacuum truck operators access the chambers through manholes set above each compartment. Boxes cannot be cleaned out if base flow remains in the inlet pipes. To block incoming flow, inflatable plugs or sandbags can be placed in the inflow pipe or in the manhole upstream. If the box is below the outfall level, additional plugs will be needed to prevent backflow. Residual material from baffle boxes is not considered hazardous and, therefore, its disposal is not problematic. In Brevard County, useable spoil is dried and used on road projects, while un-useable material is landfilled.

COSTS

Installation costs for most precast baffle boxes run between $20,000 and $30,000, depending on utilities that must be relocated to accommodate the box. Average costs are approximately $22,000. However, costs can be significantly higher for individual installations. For example, pre-design estimates for installation of a cast-in-place concrete baffle box for a 48-inch pipe in Jacksonville, Florida, are approximately $250,000. Because baffle boxes are usually retrofit into existing storm water sewers, costs are often independent of the size of the drainage area served. Most retrofit baffle boxes are about the same size, making capital costs about the same.

Good examples of this come from two Brevard County communities. A baffle box for the Cedar Lane community, which serves 0.9 acres, cost $25,027, while the Riverside baffle box, which serves 161 acres, cost $24,944. The major cost differences for drainage areas of different sizes usually result from an increase in maintenance frequency for boxes in larger drainage areas with increased runoff.

The average clean-out cost for a baffle box is $450. At an average of 1,925 kg/clean out, this is an approximate cost of $0.23 per kg of sediment removed. An average vacuum truck can clean two baffle boxes per day.